The latest trends and uses for Titanium metals in 2024

18th Oct 2024

Its unique properties, such as high strength, low density, and excellent corrosion resistance, make it a preferred material for numerous high-performance applications. Titanium's biocompatibility, durability, and ability to withstand extreme conditions further enhance its desirability. These attributes are driving its adoption in sectors ranging from aerospace to consumer goods, setting new trends and benchmarks for innovation.

Titanium's importance in industries like aerospace, medical, automotive, and marine cannot be overstated. In aerospace, its ability to endure high stress and temperatures without losing integrity is invaluable. According to Materials Today, 'Titanium is valued in aerospace for its ability to withstand extreme temperatures and stress without losing its strength and integrity.' This makes it indispensable in aircraft construction and other high-stress applications.

Moreover, the medical field highly appreciates titanium for its biocompatibility. The National Institutes of Health (NIH) states, 'Medical devices made from titanium are biocompatible, meaning they are non-toxic and not rejected by the body, making titanium the material of choice for implants and prosthetics.' This property is crucial for ensuring patient safety and the longevity of medical devices. As we look towards the future, titanium's applications are poised to grow even further, paving the way for revolutionary advancements in technology and industry.

Aerospace Innovations with Titanium

Titanium continues to be a game-changer in the aerospace industry due to its unparalleled strength-to-weight ratio. The material's ability to withstand extreme conditions without compromising performance makes it ideal for aircraft components, including airframes and engines. Recent innovations have seen titanium being used in next-generation aircraft designs, enhancing performance and fuel efficiency while reducing overall weight.

One significant benefit of titanium in aerospace is its resistance to corrosion, which is crucial for maintaining the structural integrity of aircraft exposed to harsh environments. As Materials Today highlights, 'Titanium in aerospace is not only about strength but also about maintaining that strength under extreme conditions.' This ensures that aircraft can operate safely and efficiently over longer periods.

The future potential of titanium in aerospace is immense. Emerging technologies such as additive manufacturing (3D printing) are enabling more complex and lighter titanium structures, further pushing the boundaries of aerospace design. Companies are investing heavily in research to explore new titanium alloys that can offer even better performance.

Recent case studies reveal the successful implementation of titanium in various aerospace projects. For instance, the development of the new Boeing 787 Dreamliner extensively uses titanium to reduce weight and improve fuel efficiency. These advancements highlight the critical role of titanium in the aerospace sector's evolution and its potential to drive future innovations.

Medical Advancements Using Titanium

The medical industry has long recognised the benefits of titanium, especially in the development of implants and prosthetics. Titanium's biocompatibility ensures that it is not rejected by the body, making it an ideal material for medical devices. According to the National Institutes of Health (NIH), 'Medical devices made from titanium are biocompatible, meaning they are non-toxic and not rejected by the body, making titanium the material of choice for implants and prosthetics.'

Recent advancements in medical technology have further expanded the use of titanium. Its application now extends to dental implants, joint replacements, and even cardiovascular devices. Titanium's strength and light weight contribute significantly to the durability and functionality of these medical devices.

The future potential of titanium in the medical field is promising. Research is ongoing to develop new titanium alloys that can enhance the performance of medical devices. Innovations such as 3D printing are also being utilised to create customised implants that fit patients more precisely, improving outcomes and reducing recovery times.

An example of a breakthrough medical device using titanium is the development of patient-specific implants for cranial and spinal surgeries. These implants are designed using advanced imaging techniques and 3D printing, ensuring a perfect fit and better integration with the patient's body. This innovation underscores titanium's critical role in advancing medical technology and improving patient care.

Automotive Industry Embraces Titanium

The automotive industry is increasingly turning to titanium to enhance vehicle performance and efficiency. Titanium's high strength and low density make it an ideal material for reducing the overall weight of vehicles without compromising safety. As Automotive Engineering International notes, 'The automotive industry uses titanium to reduce weight and improve fuel efficiency without compromising safety or performance.'

One of the latest applications of titanium in the automotive sector is in exhaust systems. Titanium exhausts are lighter and more durable than their steel counterparts, leading to improved fuel efficiency and performance. Additionally, titanium's resistance to high temperatures and corrosion extends the lifespan of exhaust systems, making them more cost-effective in the long run.

The potential for titanium in the automotive industry is vast. Future applications may include more extensive use in engine components, chassis, and body panels. These advancements will further reduce vehicle weight, enhance performance, and improve fuel efficiency, aligning with the industry's goals of reducing emissions and promoting sustainability.

A notable example of a car model utilising titanium is the Ford GT, which features a titanium exhaust system. This high-performance sports car benefits from the reduced weight and enhanced durability provided by titanium, highlighting the material's significant impact on automotive design and engineering.

Marine Applications of Titanium

The marine industry has long struggled with the challenge of corrosion in harsh seawater environments. Titanium's exceptional resistance to corrosion makes it an ideal material for marine applications, significantly extending the lifespan of components exposed to seawater. Marine Engineering Review states, 'Titanium's corrosion resistance makes it ideal for marine applications, significantly extending the lifespan of components exposed to seawater.'

Recent innovations have seen titanium being used in various marine applications, including shipbuilding, offshore drilling equipment, and underwater exploration vehicles. Titanium's strength and light weight contribute to improved performance and efficiency in marine operations.

The future potential of titanium in the marine industry is significant. As the demand for durable and reliable materials grows, titanium's applications are expected to expand further. Research is ongoing to develop new titanium alloys that can offer even better performance in marine environments.

An example of a marine project using titanium is the construction of titanium hulls for underwater exploration vehicles. These hulls provide enhanced durability and resistance to the corrosive effects of seawater, ensuring the longevity and reliability of these specialised vehicles.

The Rise of Titanium in Consumer Products

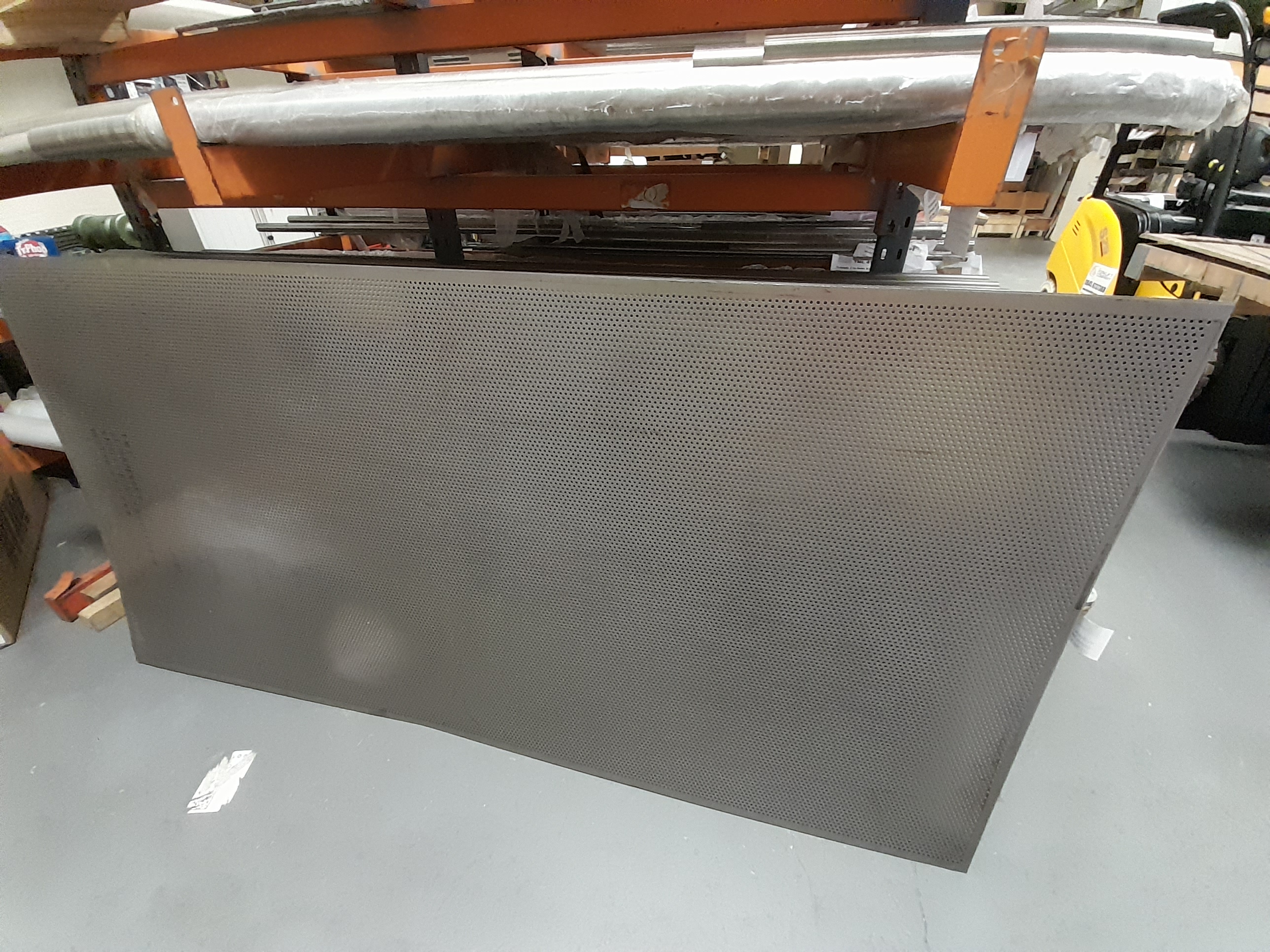

Titanium is not just limited to industrial applications; it is also making its mark in consumer products. The material's durability, light weight, and resistance to corrosion make it ideal for various household items. One of the latest trends in consumer products is the use of titanium in kitchenware, particularly chopping boards. These titanium chopping boards are praised for their durability and hygiene, making them a popular choice in 2024.

Beyond kitchenware, titanium is also being used in the fashion and accessories industry. Its strength and light weight make it an excellent choice for jewellery, watches, and even eyewear. The versatility of titanium allows for unique and innovative designs, appealing to consumers looking for both functionality and style.

The future potential of titanium in consumer products is immense. As technology advances, we can expect to see more everyday items being made from titanium, offering improved performance and longevity. The rise of titanium in consumer products underscores the material's versatility and its ability to enhance the quality and functionality of everyday items.

The trend of titanium chopping boards in 2024 highlights the growing awareness and appreciation of titanium's benefits in everyday life. These chopping boards are not only durable but also resistant to bacteria, making them a hygienic option for kitchens. This trend is a testament to titanium's increasing popularity and its expanding range of applications.

Future Prospects and Emerging Uses of Titanium

The future of titanium looks incredibly promising as new uses and applications continue to emerge across various industries. One of the most exciting areas of development is in the renewable energy sector. Titanium's durability and resistance to environmental factors make it an ideal material for wind turbines, solar panels, and other renewable energy systems. According to Renewable Energy World, 'The renewable energy sector adopts titanium for its durability and resistance to environmental factors, enhancing the efficiency and longevity of energy systems.'

Additionally, the defence sector is increasingly using titanium for armour plating and lightweight weaponry. Titanium alloys offer superior strength and durability, providing enhanced protection and performance in defence applications. This trend is set to continue as new titanium alloys and manufacturing techniques are developed.

Another emerging use of titanium is in the art and jewellery industry. Artists and designers are leveraging titanium's unique properties to create innovative and intricate designs. The material's versatility allows for a wide range of artistic expressions, from sculptures to wearable art.

In conclusion, titanium's growing importance across various sectors is undeniable. Its unique properties and versatility make it a valuable material for a wide range of applications. As we look to the future, the potential for titanium to revolutionise industries and enhance everyday life is vast. The ongoing research and development in titanium technologies will continue to drive innovation and expand the material's applications, solidifying its position as a vital resource for the future.