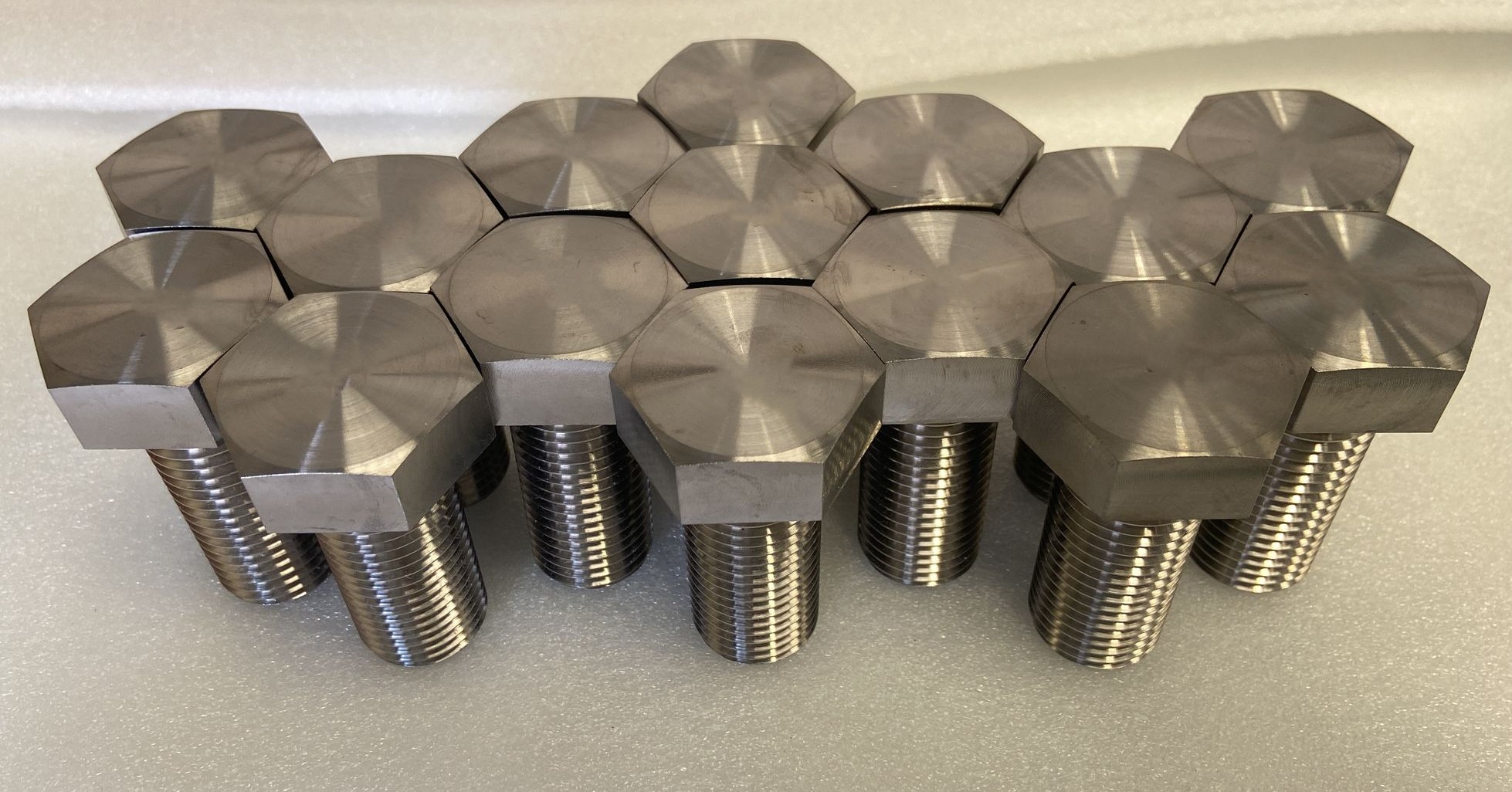

Grade 5 Titanium Bolts

11th Sep 2023

Welcome to Titanium Metals, your trusted source for high-quality titanium fasteners. In this blog post, we will explore what titanium fasteners are, their benefits, common applications, types, factors to consider when choosing them, and proper installation and maintenance techniques. Whether you are in the aerospace, automotive, or marine industry, titanium fasteners are a vital component for your projects. Let's dive in!

What are Titanium Fasteners?

Titanium fasteners are bolts, screws, nuts, washers, and other mechanical components made from titanium, a lightweight and corrosion-resistant metal. Titanium is known for its exceptional strength-to-weight ratio, making it an ideal choice for applications where weight reduction is critical. It is also highly resistant to corrosion, even in harsh environments.

Benefits of Titanium Fasteners

Titanium fasteners offer numerous advantages over fasteners made from other materials:

- Lightweight: Titanium is about 40% lighter than steel, making it ideal for applications that require weight reduction.

- Corrosion resistance: Titanium has a natural oxide layer that provides exceptional corrosion resistance, even in saltwater environments.

- Strength: Despite its lightweight nature, titanium is incredibly strong, making it suitable for high-stress applications.

- Temperature resistance: Titanium can withstand extreme temperatures, making it suitable for applications in both high-temperature and cryogenic environments.

- Biocompatibility: Titanium is biocompatible, meaning it is well tolerated by the human body. This makes it ideal for medical implants.

Common Applications of Titanium Fasteners

Titanium fasteners find applications in various industries, including:

- Aerospace: Titanium fasteners are widely used in the aerospace industry due to their lightweight nature, strength, and corrosion resistance.

- Automotive: In the automotive industry, titanium fasteners are used to reduce weight, improve fuel efficiency, and enhance performance.

- Marine: Titanium fasteners are resistant to saltwater corrosion, making them ideal for marine applications.

- Sports equipment: Titanium fasteners are commonly used in sports equipment, such as bicycles and golf clubs, to reduce weight without compromising strength.

- Medical: Titanium fasteners are used in medical implants, such as joint replacements and dental implants, due to their biocompatibility and corrosion resistance.

Types of Titanium Fasteners

There are various types of titanium fasteners available, including:

| Type | Description |

|---|---|

| Bolts | Titanium bolts are threaded fasteners used to hold two or more components together. They come in various sizes and designs. |

| Screws | Titanium screws are similar to bolts but have a pointed end. They are commonly used to attach components to a surface. |

| Nuts | Titanium nuts are used in conjunction with bolts or screws to secure components in place. They come in different shapes, such as hex nuts and wing nuts. |

| Washers | Titanium washers are thin plates with a hole in the middle. They are placed between a fastener and the surface it is being tightened against to distribute the load and prevent damage. |

Factors to Consider When Choosing Titanium Fasteners

When selecting titanium fasteners for your application, consider the following factors:

- Strength requirements: Determine the strength needed for your specific application to ensure you choose the right grade of titanium.

- Corrosion resistance: Consider the environment in which the fasteners will be used and choose a grade of titanium with adequate corrosion resistance.

- Size and thread: Ensure the fastener size and thread match the components you are connecting.

- Temperature resistance: If your application involves extreme temperatures, choose a titanium grade that can withstand those conditions.

- Cost: Consider your budget and balance it with the desired properties of the fasteners.

Conclusion

Titanium fasteners offer numerous benefits, including lightweight, strength, corrosion resistance, and temperature resistance. They find applications in various industries, such as aerospace, automotive, marine, and medical. When choosing titanium fasteners, consider factors like strength requirements, corrosion resistance, size, thread, temperature resistance, and cost. By following proper installation and maintenance practices, you can ensure the longevity and performance of titanium fasteners in your projects. Contact Titanium Metals today to explore our wide range of high-quality titanium fasteners for your specific needs.